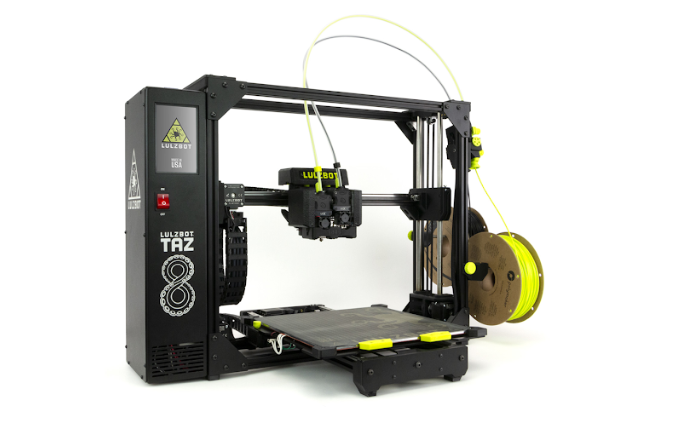

AnkerMake M5 3D Printer: Fast, Precise 3D Printing with AI Monitoring

AnkerMake’s M5 3D Printer combines 5X faster printing (500 mm/s) with 0.1 mm precision, automatic bed leveling, AI-driven error detection, and user-friendly setup. It's ideal for hobbyists and pros seeking speed and reliability.

AnkerMake’s M5 3D Printer stands out in the crowded desktop market because it combines high speed with remarkable precision and intelligent monitoring. Designed for hobbyists and professionals alike, it promises to shorten print times without sacrificing quality. It also comes from AnkerMake, a brand known for user‑friendly tech, which means getting started is easier than with many competitors.

Why it matters

Choosing the right 3D printer affects more than just how quickly parts appear on your workbench. A well‑designed machine reduces failed prints, lowers material waste and frees up your time for design. The M5’s combination of speed, accuracy and smart monitoring means you spend less time tinkering and more time making. For small businesses and makers who need prototypes or custom parts on demand, these gains translate into faster turnaround and better quality at a price that still fits on a desktop.

Key benefits

- Blazing print speed – A standard speed up to 500 mm/s with a multi‑stage gear system and PowerBoost motor means jobs finish up to five times faster than many budget machines.

- Impressive precision – With advertised accuracy of ±0.1 mm and a 0.4 mm nozzle that accepts alternatives from 0.2 mm to 0.8 mm, the M5 produces clean surfaces and detailed features.

- Large build volume – A 235 × 235 × 250 mm build area lets you print bigger objects or nest multiple small parts in a single run.

- Onboard AI camera – The printer includes an integrated camera that can detect spaghetti failures and send alerts, so you can stop a misprint before it wastes hours of material.

- All‑metal direct extruder – A 9.37:1 gear reduction and 0.8 N·m of torque improve filament grip and allow consistent extrusion even at high speeds.

- Multi‑device control – Wi‑Fi and app connectivity mean you can start, monitor and pause prints from your phone or computer rather than being tethered to the printer.

- Broad material compatibility – Support for PLA, PETG, TPU and even some ABS makes the M5 versatile enough for functional parts, prototypes and flexible components.

Proof & specs

MatterHackers reports that the AnkerMake M5 uses a direct‑drive extruder with a multi‑stage gear reduction and a PowerBoost motor to deliver high torque and maintain filament flow at speeds up to 500 mm/s. This hardware, combined with a stabilized motion algorithm and double‑belt driveshaft, allows the printer to accelerate at 2 500 mm/s² without sacrificing print quality.

The machine’s build volume is 235 mm long, 235 mm wide and 250 mm high, giving it more capacity than typical entry‑level printers. AnkerMake advertises positional accuracy within ±0.1 mm, which helps ensure dimensional consistency across successive parts. The stock nozzle is 0.4 mm but can be swapped for 0.2, 0.6 or 0.8 mm to balance speed versus detail. Filament diameter is the standard 1.75 mm, and the M5 can print PLA, PETG, TPU and ABS, expanding material options for designers.

An automatic bed‑leveling routine, combined with an auto‑tensioned belt system, reduces setup time and keeps the first layer consistent. The integrated HD camera not only supports live monitoring but also uses AI algorithms to detect extrusion failures and pauses the job if a problem occurs, giving you a chance to intervene. This system pairs with the AnkerMake app and Cloud service, allowing remote control from multiple devices. Together, these features demonstrate a thoughtful balance between high‑end performance and ease of use.

Not ideal for …

Despite its impressive feature set, the AnkerMake M5 might not be the perfect choice for everyone. If you need industrial‑grade materials like nylon, polycarbonate or carbon‑fiber composites, the M5’s hotend and enclosure are not rated for those higher‑temperature filaments. Large production runs may also reveal the limits of the 250 mm Z‑height compared with bigger prosumer machines.

While the camera and app features help beginners, some users have reported that early firmware updates were needed to unlock all advertised speeds. If you prefer a completely open‑source ecosystem for firmware and slicer settings, you may find the AnkerMake environment more closed than DIY kits. Finally, although the price reflects its hardware, it sits above budget printers, so makers on a strict budget could consider a slower but cheaper alternative.