Snapmaker 2.0 A350T: Modular 3-in-1 3D Printer, Laser & CNC

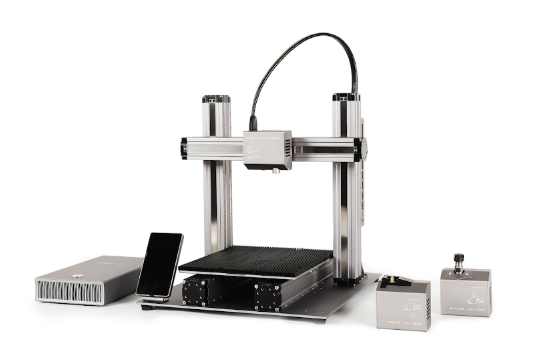

The Snapmaker 2.0 A350T modular 3‑in‑1 machine combines high‑quality 3D printing, laser engraving and CNC carving in a single compact unit. For makers who value versatility, it eliminates the need for separate tools and makes switching between fabrication methods straightforward. This all‑in‑one approach suits hobbyists, educators and small businesses that want multiple capabilities but don’t have room for an entire workshop.

Why it matters

Owning a modular machine that handles additive, subtractive and laser processes can dramatically expand what you can create. The A350T’s build volume of 320 × 350 × 330 mm rivals many dedicated 3D printers yet it also engraves and cuts with a diode laser and mills wood or plastic using a CNC head. By swapping the tool head, you can 3D print a functional bracket, laser‑engrave a personalized plaque and carve a wooden inlay without re‑configuring your workspace. For classrooms and makerspaces, this flexibility means students learn multiple manufacturing techniques on one platform, reducing clutter and maintenance.

Key benefits

- All‑in‑one versatility – With interchangeable tool heads for 3D printing, laser engraving and CNC carving, one machine handles three distinct fabrication methods.

- Generous build volume – The A350T provides up to 320 × 350 × 330 mm of workspace, matching or exceeding many single‑purpose printers.

- Upgradeable and modular – Snapmaker’s platform design allows you to expand with addons like an enclosure, Air Purifier and rotary module as your needs grow.

- Material diversity – Supports common filaments like PLA, ABS, PETG and TPU and can engrave or carve wood, paper, leather and plastics.

Proof & specs

The Snapmaker 2.0 A350T uses a swappable tool system that delivers three manufacturing modes. Its 3D printing module uses a direct‑drive extruder and heated bed to print at up to 275 °C, accommodating filaments from PLA to PETG and wood‑filled blends. The laser module is a 1.6 W class 4 diode laser capable of engraving intricate patterns and cutting thin woods, leather, fabrics and paper, while the CNC module uses an ER11 collet and dual linear rails to carve soft woods and plastics with precision. A newly designed cooling system and improved power management reduce noise and vibration compared to earlier models.

In the A350T configuration the print volume measures 320 mm × 350 mm × 330 mm, giving ample space for large prototypes and multi‑part builds. Snapmaker also offers a smaller A250T version with a 230 mm × 250 mm × 235 mm build volume for users with tighter spaces. Each kit includes the 3D printing module, laser engraving and cutting module, CNC carving module, a filament spool, clamps, calibration card, work surface and Snapmaker Luban software for unified control. Optional addons like the enclosure help control fumes from laser cutting and maintain a stable temperature for printing.

The machine’s aluminum alloy frame and linear modules ensure rigid motion control, and the touchscreen controller with intuitive menus makes mode switching easy. Compared with buying separate machines, the Snapmaker 2.0 A350T reduces footprint and simplifies workflow. Users can import models in common formats like STL and SVG into the Luban software, slice for printing, generate G‑code for the laser or prepare tool paths for CNC in a single interface, streamlining the learning curve.

Not ideal for …

Despite its versatility, a modular 3‑in‑1 device is not perfect for every user. Dedicated specialists may prefer single‑purpose machines tuned for maximum performance in a given process; for example, high‑end resin printers will outperform the Snapmaker in surface finish, and industrial CNC routers will cut metals that this machine cannot. Beginners should expect a learning curve when calibrating three different modules, and the combined tool head system means tool changes add set‑up time between jobs. The large footprint and premium price may also be excessive if you only need basic 3D printing. Hobbyists focused solely on PLA prints could choose a simpler and more affordable printer, while professionals working with metals or very high‑temperature polymers should look to specialized equipment.

Overall, the Snapmaker 2.0 A350T excels as a multi‑discipline fabrication platform for makers seeking flexibility and space efficiency. Its modular design, generous build volume and comprehensive accessory ecosystem make it a compelling choice for workshop environments where space is at a premium and creativity demands multiple manufacturing methods.